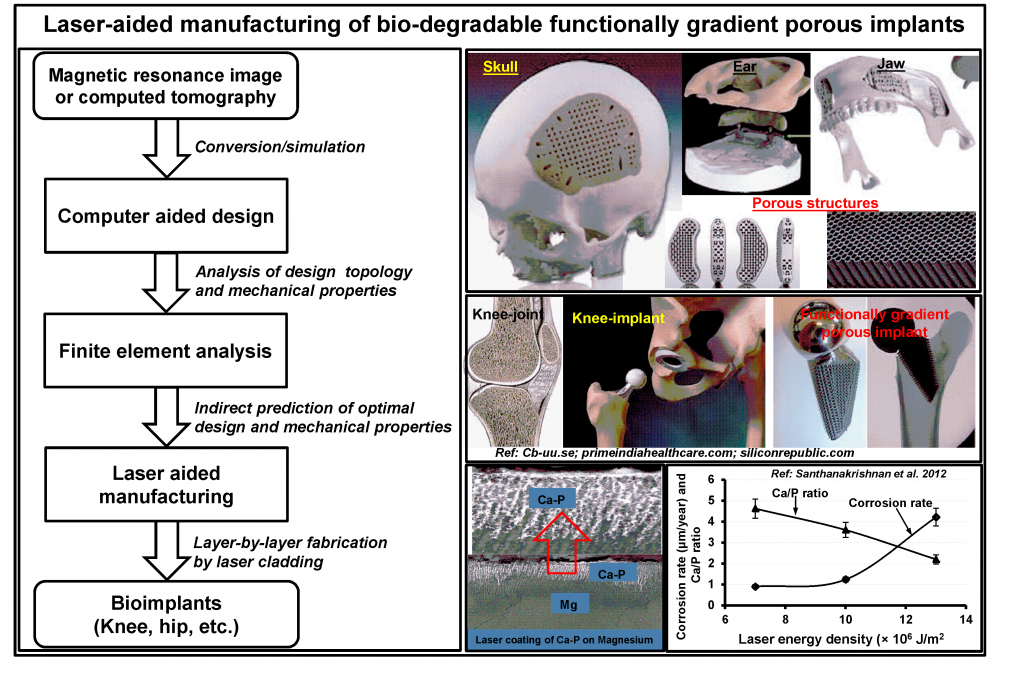

Laser-aided manufacturing of biodegradable functionally-gradient porous implants

Bone gives structural support to the human body which is made of multiphase matrix such as collagen (30%) and hydroxyapatite (70%). Hard bone-tissues (hip, knee, shoulder, elbow) need to be replaced or repaired due to aging, accidents, sports, and war injuries. Today’s market potential is around $32 billion dollars and expected to grow $50 billion dollars by 2020. Traditionally, stainless steel, cobalt-chromium, titanium (SSCCT) have been widely used as biomaterials for fabricating bioimplants.The structural and functional properties of SSCCT are not compatible with human bone and therefore lead to anatomical complications and the shorter lifespan of these bioimplants lead to post-surgery management. In order to avoid the issues of SSCCT, new generation biomaterials have come up such as magnesium (Mg) and hydroxypatitte (HAp) which acquire near elastic modulus and compressive strength to human bone. In addition to near bone’s properties, Mg is also an essential element in human metabolism, cofactor for many enzymes and with HAp which is a catalyst for cell-bone growth; these replace efficiently the SSCCT bioimplants. Mg-HAp based implants are widely acknowledged as human-body friendly where its decay is linear in the physical environment and concurrently triggering the growth of the bone. It is possible to fabricate these implants by using laser technology. The structural details of patients’ injured parts are recorded with magnetic resonance imaging (MRI) then transferred to computers for simulation and optimization. These data is used by laser technology to fabricate bioimplants layer-by-layer (functionally-gradient porous) by injecting the bioparticles (Mg, HAp).