Materials Design

Group

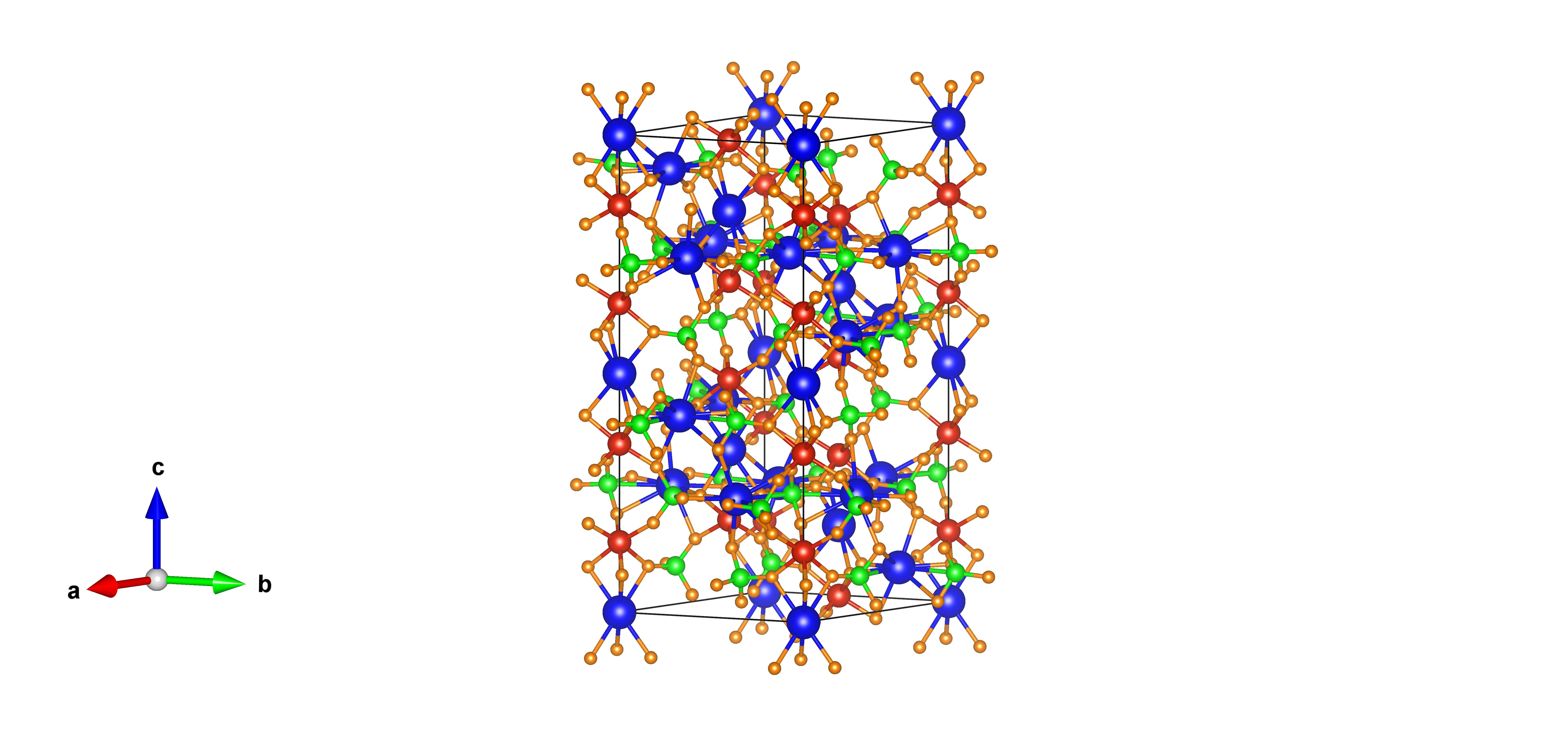

3-D Interfaces

- Thermodynamics suggests that metal/ceramic interfaces does not favor intermixing hence chemically sharp.

- Using a combination of experiments and atomistic modeling we aim to understand 3-D metal/ceramic interfaces.

- Metals and alloys are sputter deposited on ceramics using ATS 500 magnetron sputtering machine.

Energy conversion and storage systems

- We use atomistic modeling to understanding cyclic stability of Na and Li ion electrode materials.

- This helps experimentalist to tune their growth parameters to improve battery performance.

- Using atomistic modeling we make prediction of new possible cathode and anode materials and photovoltaic materials.

- We are exploring possibility of using high entropy oxides as anode materials, using atomistic modeling.

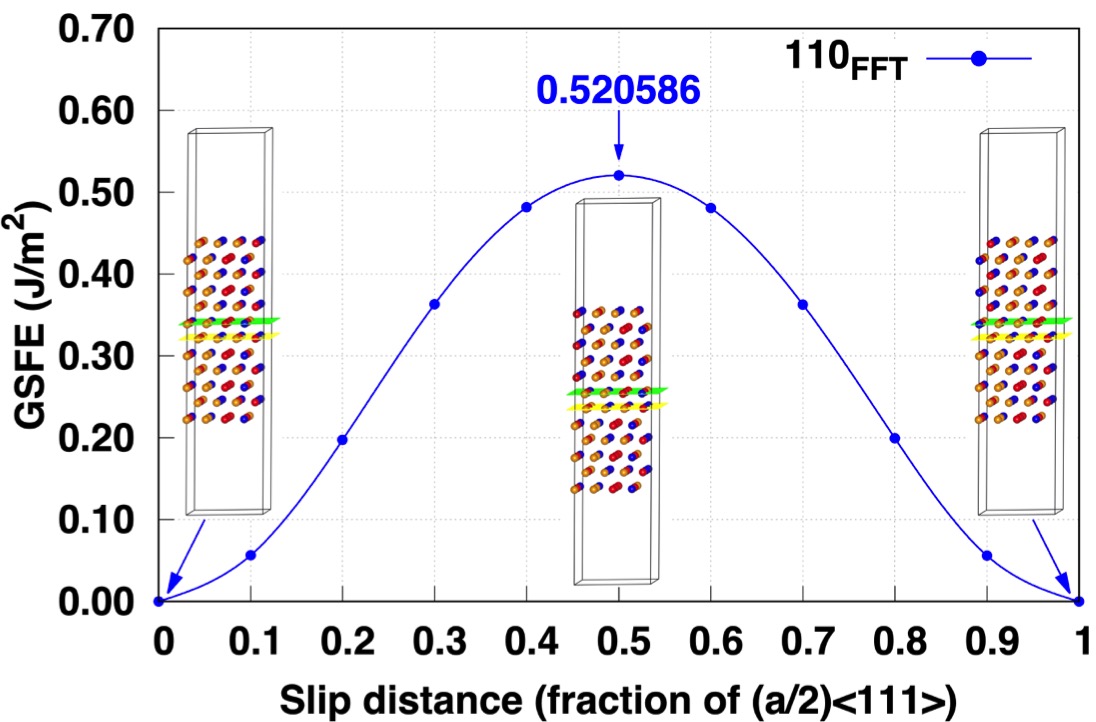

Atomistic modeling of materials with complex chemistries

- Being able to accurately capture bonding in materials with complex chemistries like high entropy alloys is necessary to predict properties.

- Using atomistic modeling we accurately calculate SFE of high entropy alloys have complex chemistries.

- Understanding heterogeneous catalyst: Using first-principles modelling based on density functional theory we show that oxides implanted with transition metals can act as supports for noble metal single atoms and prevent their agglomeration.

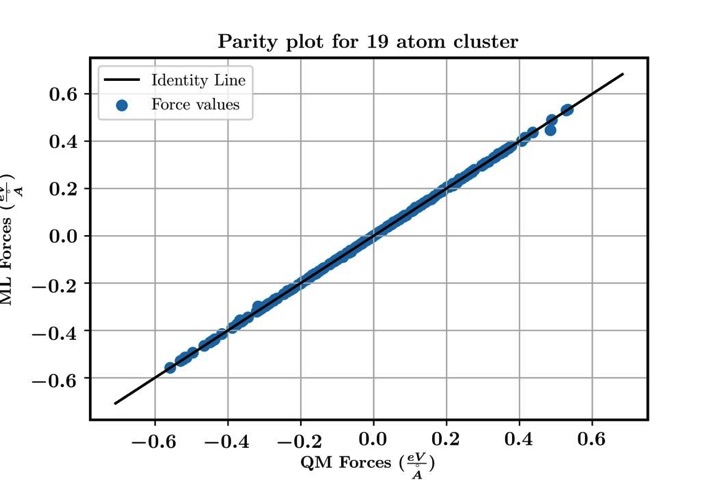

Machine learning assisted atomistic modeling

- In order to extend capability of first-principles electronic structure calculations, we use machine-learning methods.

- Development of machine-learned potentials allows us to accelerating ab initio molecular dynamics.

- The machine learning models do not have a fixed functional form making them very flexible to learn complex relationships and any correlations present in the data.

Role of Interfaces in Mechanical Response of Nano-heterostructures

- Established a method to quantify nucleation stresses for dislocations via in situ high-resolution transmission electron microscope experiment coupled with density functional theory calculation.

- Explained pure-shuffle nucleation of deformation twins in hexagonal-close-packed metals.

- Explained origin of multiple in-plane orientation of Cu in Cu/TiN nano-heterostructures.

- Explained role of chemistry at metal-nitride interfaces in dictating mechanical and structural properties metal/nitride nano-heterostructures.

Materials growth mechanisms

- Explained change in growth directions in ZnO nanowires under CO rich environment.

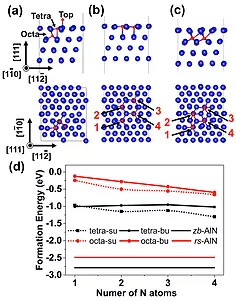

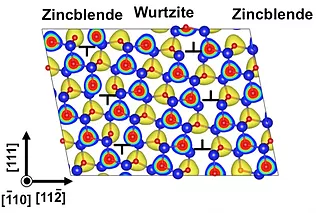

- Explained growth and stress-induced phase transformation of metastable zinc-blende AlN nanolayer grown by magnetron sputtering.

- Explained growth of MgCr2O4 spinel in Cr/MgO heterostructure under ion radiation.

- Explained thermodynamic driving force behind cations substitution in substoichiometric titania.

- Explained origin of chemically diffused interfaces across Ti/TiN nano-heterostructures, in collaboration with neutron reflectometry measurements.

Optoelectronic Properties of Materials

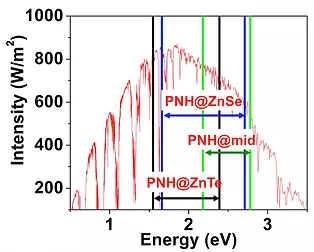

- Suggested a practical way to engineer the bandgap of II-VI and III-V semiconductor through epitaxial strains in nano-heterostructures.

- This involved calculation of bandgap using density functional theory (DFT), hybrid DFT (HSE) and many body perturbation GW methods.

- Explained improved scintillation properties of LuxGd3-xAlxGa5-xO12 multicomponent garnets.

- Explained how band-edge engineering via doping can independently tailor either the conduction or valence band. These ideas extend to other complex oxides, and other applications requiring precise control of band gaps and edges, such as the rational design of optoelectronic devices.

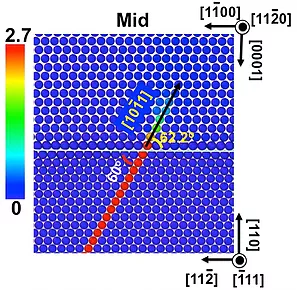

Modeling of Line Defect from First-Principles

- For the first time, using density functional theory (DFT), computed the lattice resistance to glide (Peierls stress) for the viable slip systems of multicomponent material (TiN).

- Using DFT calculation we show that six-layer bi-phase zinc blende AlN and wurtzite AlN can form a sharp interface. Three Shockley partials with the Burgers vectors pile up vertically and form the interface which separates the z-AlN from the w-AlN.