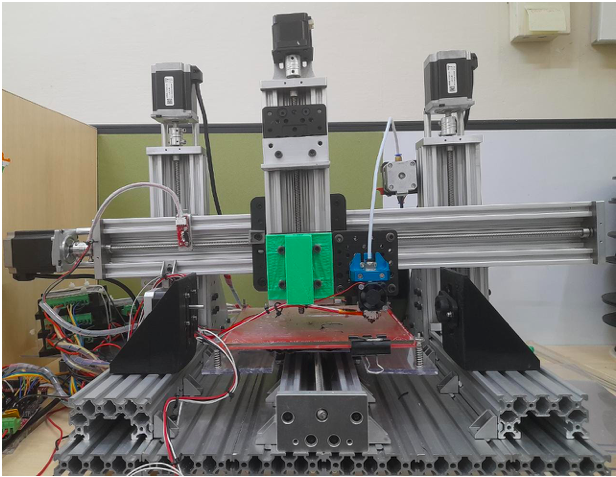

4D printing defined as “3D printing + time” with the fourth dimension to be time. 4D printing refers to single-material or multi-material printing of a device or object that can be transformed from a 1D strand into pre-programmed 3D shape, from a 2D surface into preprogramed 3D shape and is capable of morphing between different dimensions. This advanced technology enables us to fabricate dynamic structures which can change their shapes, functions, or properties along with the time when appropriate external stimuli (e.g., water, pH, temperature) are applied.

We work with stimuli responsive smart biopolymers. We perform different experimental characterization and develop 2D or 3D continuum scale models to predict the behaviors and the mechanisms involved.

Stimuli responsive biopolymers with advanced functionalities have found a wide range of futuristic applications as soft actuators morphing medical devices artificial muscles, and soft robotics, sensors, etc. We work with biopolymers (chitosan, PVA etc) which responds to solvent (water, the simplest one) as external trigger. The films actuate or folds and unfolds when exposed to solvent.

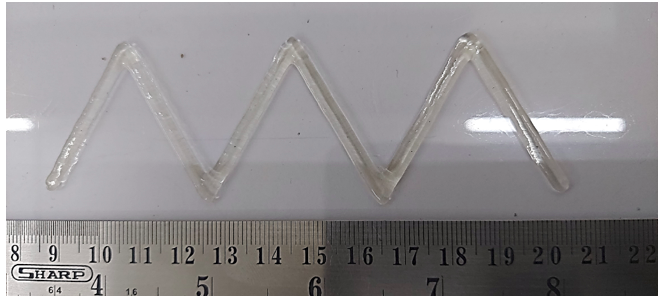

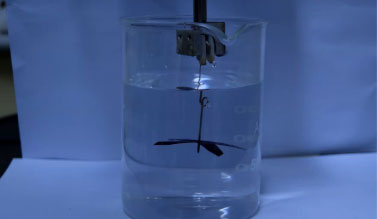

Actuation of biopolymer (chitosan) thin film when exposed to solvent

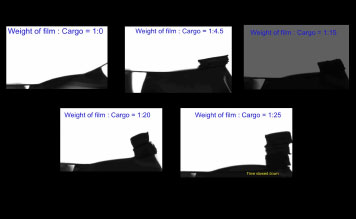

Experiment indicating load carrying ability of thin film during actuation or folding

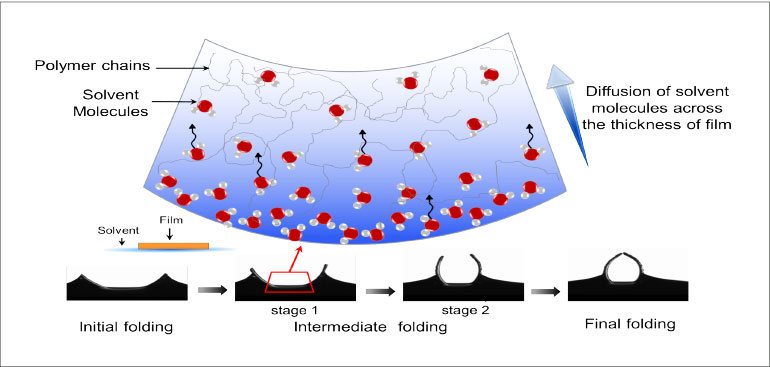

The folding is due to differential swelling across the thickness of the film caused due to concentration gradient of solvent. During folding, the polymer chains at the bottom layer experience tension, whereas the top layer chains are in compression. With the passage of time, water diffuses further through the layers of the film, reducing the concentration gradient, thus relaxing the polymer chains to go back to their equilibrium state.

Schematic showing the concentration gradient of solvent molecules developed during folding

Possible application in gripping of objects

Inside solvent, Possible application in wrapping of an object

Interestingly, this folding and unfolding behaviour can be controlled by playing with the properties of the polymer matrix and the solvent. For example, in one of our works, we have added some organic solvent to the water (used as trigger) and could achieve irreversible or permanent folding. This permanent folding behaviour can be used for gripping and lifting some materials.

It is not always possible or even convenient to have water in bulk around to trigger this folding. In one of our works, we have applied pNIPAM layer as a source of water or solvent supply when the temperature goes beyond the LCST of it (which is around 35oC). Figure 1 illustrates the response of chitosan/pNipam bilayer to temperature. As the lower critical solution temperature of synthesized pNipam particles is about 32.5 °C, the actuation of the film begins around 32.5 °C - 35 °C. As exemplified in Figure 1A, upon increasing the temperature to 35 °C, water released by pNipam goes to the chitosan and triggers the actuator to undergo out of the plane folding and unfolding. Figure 1B presents the folded state of the actuator, where the pNipam chains become dehydrated and collapsed due to the increase of temperature above the LCST of the microgels. Figure 1C and Figure 1D represent the unfolded state of chitosan/pNipam bilayer,

Schematic showing how pNipam layer can be applied as source of solvent necessary to trigger actuation

Flapping of Butterfly as Temperature Touch 35 degree

As understandable from the above discussion, that diffusion of solvent results in concentration gradient which leads to displacement field, showing up in the form of folding. During this phenomenon, the diffusion affects the mechanical properties of the polymer matrix, which in turn affects the diffusion. Thus it is a coupled diffusion deformation mechanism. we develop a model based on the coupled diffusion-deformation mechanism which can predict the large deformation caused during this reversible folding behavior of a polymeric thin film. The formulation incorporates a concentration dependent Young’s modulus variation. This continuum scale model provides us a detailed insight in to the concentration gradient and strain field developed during the process of folding and unfolding.

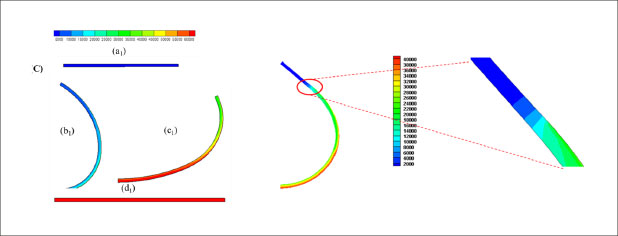

Diffusion Couple Deformation FE Modeling of Folding: Indicating curvature and concentration gradient

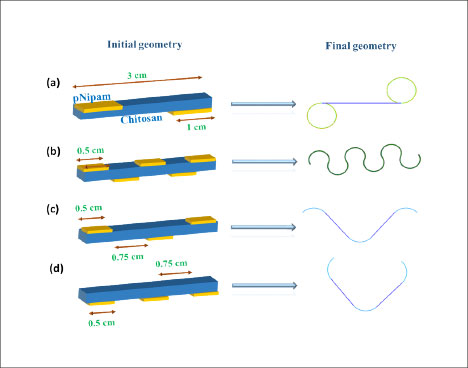

Different shapes and patterns that can be obtained with different positioning of pNipam: FEM Study

Th`e above examples and discussions are related to single layer polymer film. To bring in more diverse applications and apply multiple trigger, it is necessary to apply bilayer so that second layer can bring additional functionalities. In one of our works, we have introduced PMMA as second layer at the top of the active chitosan layer. When we talk of a bilayer or multilayer, the influence or role of ‘interface’ is inevitable. We have showed, both through modelling and experimentally) that the strength of this interface between PMMA and Chitosan can be tuned (strong, weak, weaker, no interface etc) to achieve different folding behaviour. Continuum scale models were built to simulate the experimentally obtained interface conditions.

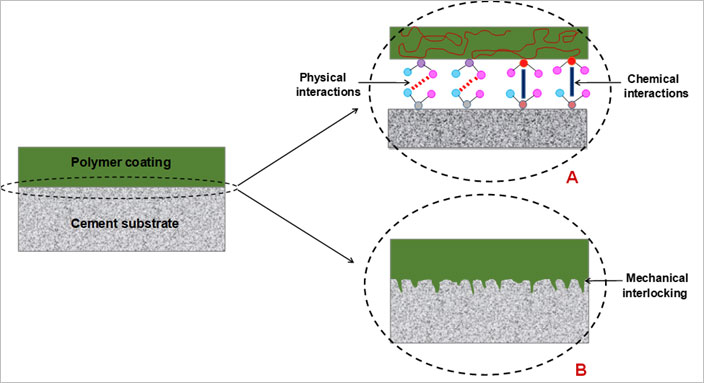

The application of polymer coating on concrete surfaces is increasing significantly, both as protective coating and/or as aesthetic coating. The applied polymers are of varying functional groups, such as, epoxy, PMMA, Poly-urethane etc. It is an usual practice in construction industry to coat polymers on concrete surface either when it is completely hard, or when it is old enough. Applying different experimental methods and phase-field modeling techniques, we are trying to determine the most appropriate window for coating a certain polymer on concrete/cement surface so as to obtain the highest interfacial shear strength.

Factors contributing to interfacial adhesion between cement paste and polymer coating

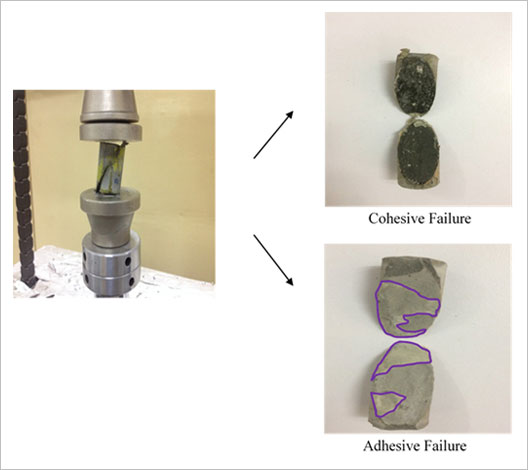

Slant shear test for evaluating shear strength of cement-polymer interface. Also showing two types of failures observed

The continuum scale FEM model helps us in predicting the crack propagation at the interface and the distribution of stresses around it.

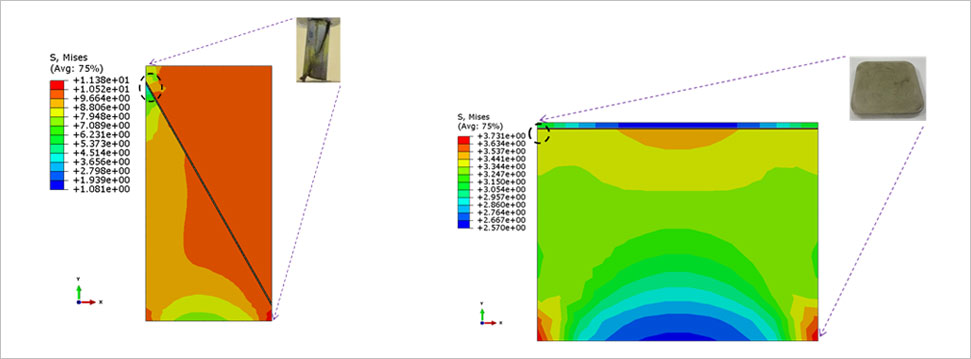

Stress contours obtained from FEM study simulating a) slant shear test b) pull-off test

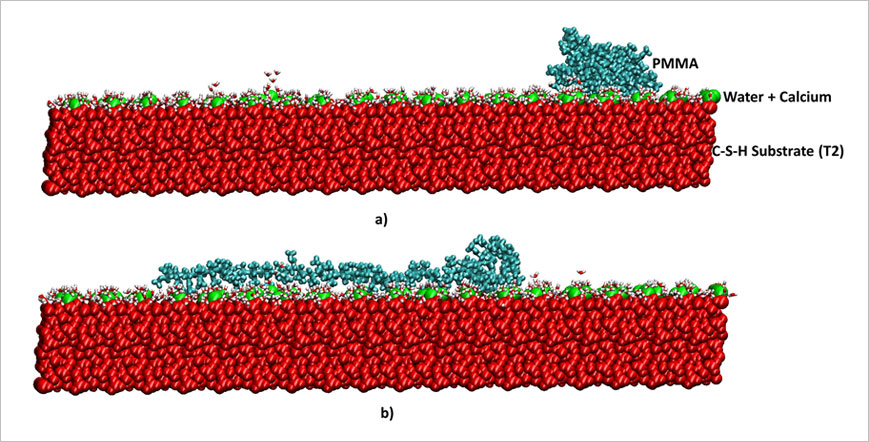

Molecular Mechanism involved in Polymer-Cement Interaction studied applying MD

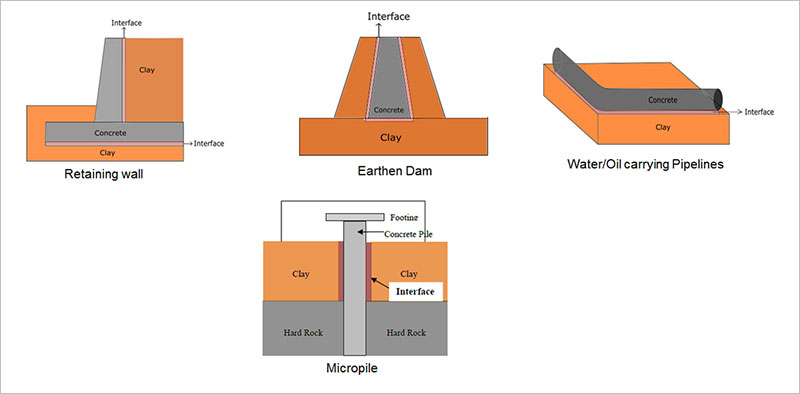

In another project, we are working on developing interfacing between concrete and clay (particularly smectite group). It is challenging to design a polymer or polymer blend which can interact with the functional group of both the cement surface and clay surface so as to form good interface. It is important to determine the right environment of coating, in terms of instant during hydration of cement and also the clay condition.

Possible geotechnical application where concrete-clay interface encountered.

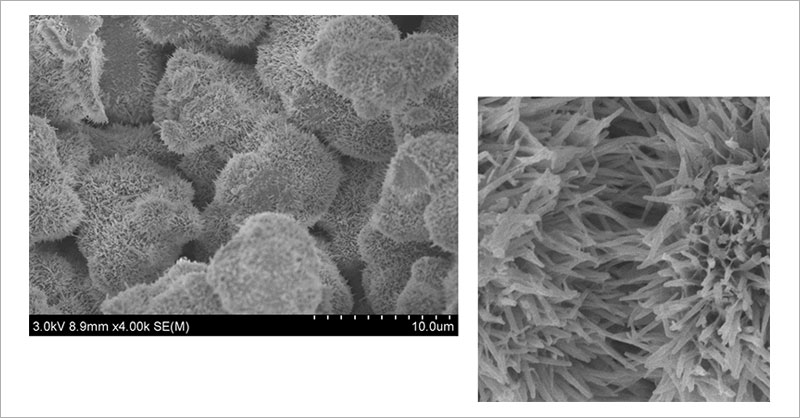

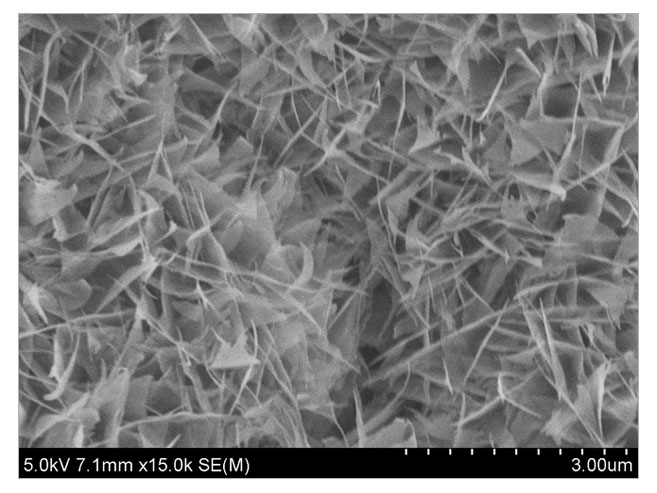

We work on fundamentals of cement hydration, following multiscale study approach, both experimentally and simulations. We are primarily interested on the mechanical properties of cement paste at the initial days of hydration. In one of our recent works, we reported that the needle like interfaces between cement grain plays a major role in determining the mechanical properties. SEM images indicates that these needles are unique to the minerals (C3S, C2S, C3A, etc) and state of hydration (7days, 14day, 28days, etc.). We have combined the microstructures obtained from SEM images, the mechanical properties from Nanoidentation and Finite Element Method to develop multiscale model capable of predicting mechanical properties of hydrating C3S and C2S. Slowly, we would like to develop a model for cement as a whole.

C3S grains and needle microstructure during hydration

C2S grains and needle microstructure during hydration

Multiscale experimental and modeling scheme incorporating needle microstructure

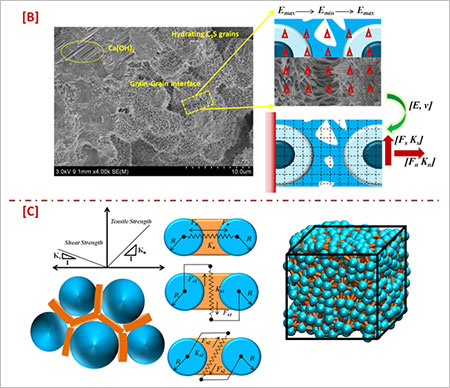

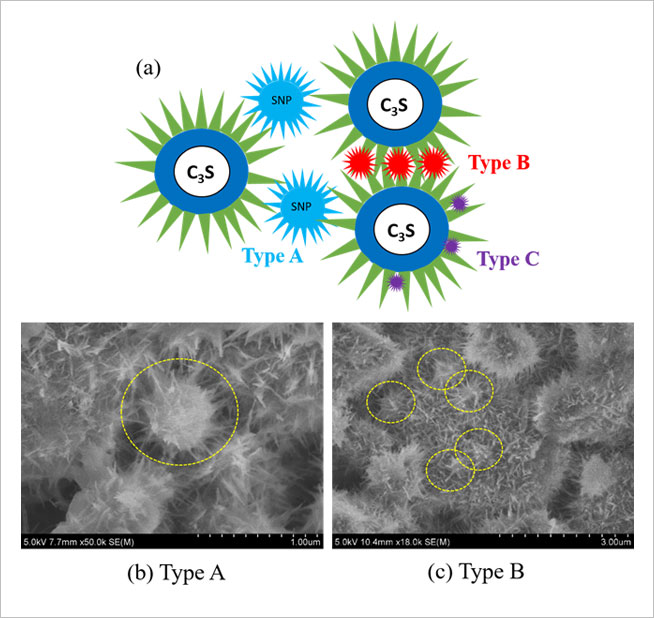

We have applied our needle microstructure based multiscale model to understand the possible mechanism how Silica Nanoparticle (SNP) modifies mechanical properties of cement.

Needle microstructure of Silica Nanoparticle (SNP) doped cement

We apply MD to understand the hydrating characteristics of different cement mineral surfaces at the molecular length scale. We have noticed that the behavior (static and dynamic) of the water molecules are different depending on the nature of surfaces at the nearest proximity.

We study the mechanical responses of polymer thin films, their interfaces, etc. applying combination of experimental techniques and FEM and/or Molecular Dynamics Simulations depending on the problem need. Both experimentally and through continuum models, we characterize, different polymer nanocomposites we synthesize in our lab.

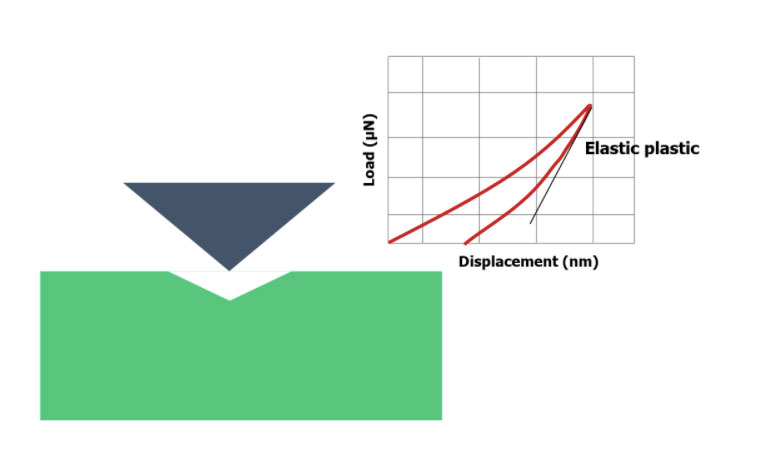

Nanoindentation and Load-Displacement Plot

We find single and multiple layers of polymer thin film (30 to 500 nanometer thick) in different engineering, electronic, optical, and data storage applications. Tissue regeneration, implants, stents, as well as drug delivery are some of the emerging biomedical applications of thin films. In a thin film system, with two or more layers of coating, an interface plays an extremely important role in determining the overall behaviour, performance and characteristics of the system. We, in our group adopt, nanomechanical techniques including nanoindentation, nanoscratch and nano-dynamic mechanical analysis (nanoDMA) to study and characterize these interfaces.

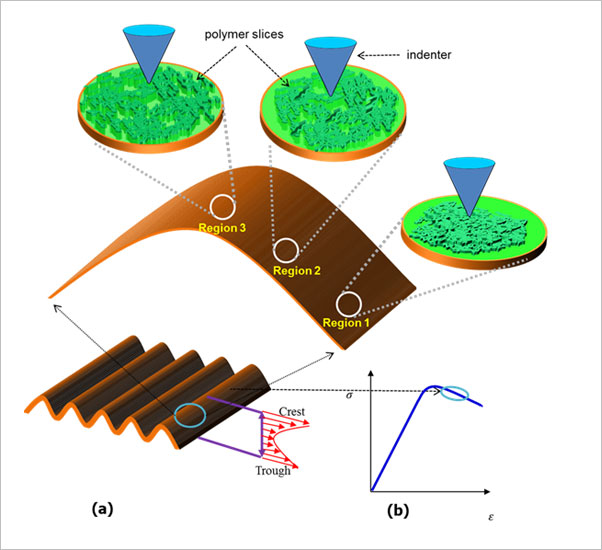

Schematic diagram showing strain distribution on wrinkled surface at different regions

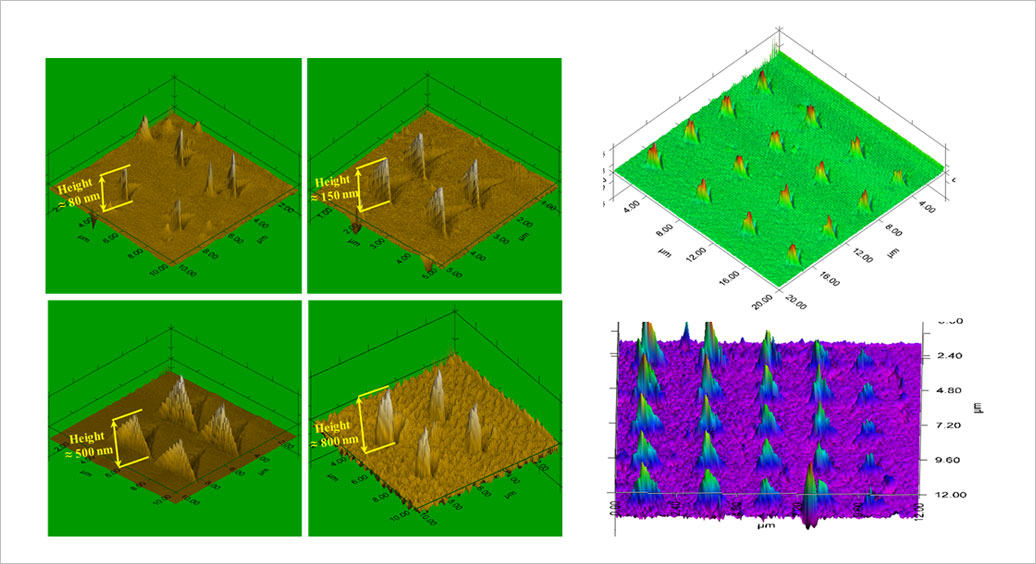

Synthesis of Nanopillar of uniform and varying size taking help of Nanoindentation

One of the major difficulties that we encounter while measuring the modulus and hardness of thin film is the ‘substrate effect’. Basically, when you are indenting and going past certain depth, the properties of the substrate start influencing your measured film properties significantly. Then we need to separate out this substrate effect from the measured composite values. This ‘substrate effect’ however, can also be used to our advantage. For example, in one of our works, we have determined the property of an inaccessible substrate, under changing temperature environment, making use of this ‘substrate effect’. We used experimental data and Finite Element Modeling in the same study to determine the necessary properties (including glass transition temperature of the substrate).

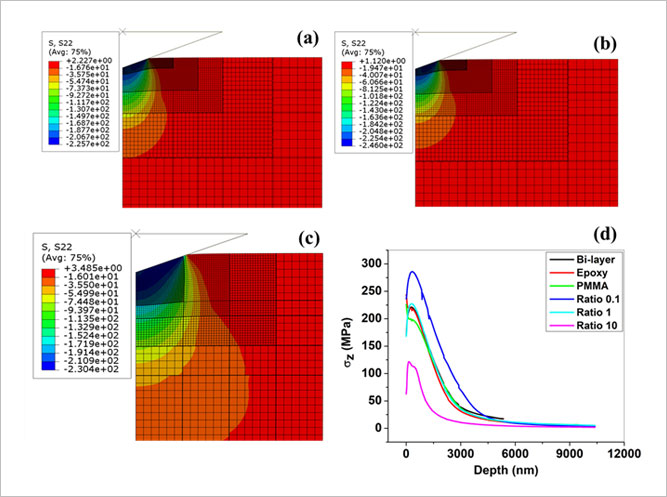

Stress contours beneath the indenter for (a) PMMA, (b) epoxy, (c) bi-later at 300C (d) The variation of sz beneath the indenter obtained from FEA

In another work, applying FEM and Nanomechanical experimental techniques, we are trying to determine the role of different types of water present, in the overall mechanical properties of a thin film.

The deformation characteristics of polymer films significantly depends on the response (relaxation, sliding, etc) of the polymer chains to mechanical loading. Besides, another factor which plays a major role is relatively difficult to understand is the response of the free volume present in the matrix.

For saturated and partially saturated films, the phenomenon is even more complex, since the stress strain response depends not only on the free volume, but also on how those free volumes are occupied by water and the type of water, such as free water, bound water etc. occupying those. Applying molecular dynamics simulations we have studied the morphological changes in the free volumes at different strain percentage and more interestingly for different degrees of hydration. One of our results indicate (as shown in figure below) that at low strain percentage, the free volume mainly undergo coalescence, whereas, at higher strain percentage, dissociation of free volume takes place.

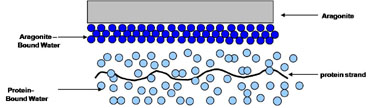

Nacre, the inner shiny part of the seashells (Fig 1)is composed of 90-95% aragonite (CaCO3) and rest organics mainly in the form of proteins and glycoproteins. The aragonite platelets are several microns in dimension in X and Y directions and only few nanometers (10-9) in Z directions. These aragonite platelets are stacked one over another with organics wrapped around it giving rise to a layered nanocomposite (Fig 2).

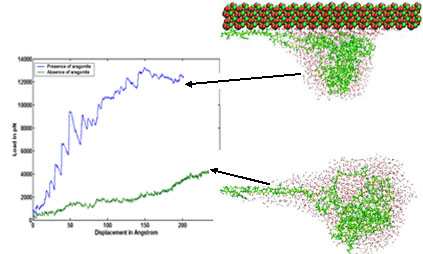

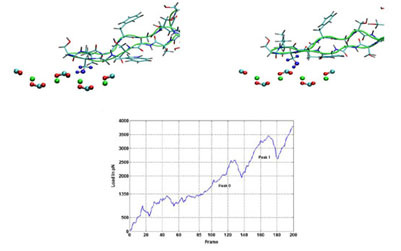

Nacre is widely studied as a model biomimetic system for next generation advanced materials. The fracture toughness of nacre is about 3 orders of magnitude higher than the pure aragonite. Previous studies reveal the possible contributions of different features of microstructures to this property of nacre. The organics present in nacre shows a high elastic modulus (15-20 GPa) besides its ability to undergo large deformation before failure. Our studies attempt on understanding the possible reasons of this behavior of organics.

As a part of this study, we focus on understanding the influence of mineral (aragonite) proximity on the mechanical behavior of organics (protein domain) in nacre.

Fig1: Inner Part of Sea Shell (Nacre)

Fig2: SEM structure of nacre showing the platelets and organics (courtesy: Katti. et.al)

Fig 3: Load Displacement plot for protein domain pulled in presence(blue) and in absence(green) of aragonite

Fig 4: The latching action giving rise to the peaks in L-D curve. On left, where the latching is just forming corresponds to the base of the peak and on right where the latching is about to break corresponds to the top of the peak

Fig 5: Showing the molecular interaction between carbonate and water molecules

Fig 6: Schematic representaion of different components of interaction (courtesy: Katti. et.al)

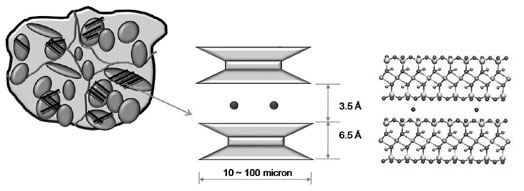

Montmorillonite belongs to the smectite group of clay minerals. It is most widely studied clay minerals because of it high swelling nature.

Fig 1: Different length scales of clay, schematic representation of T-O-T structure and the molecular model of dry sodium montmorillonite showing T-O-T layers.

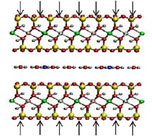

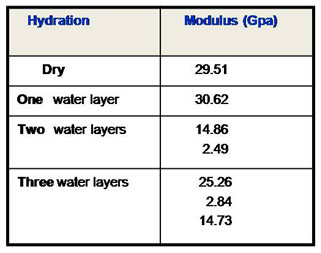

The interlayer of sodium montmorillonite was saturated with different water contents and then compressive load was applied. The load deformation (stress-strain) characteristics were compared for different cases and most importantly the interactions of the water molecules with the clay siloxane surface (silica-oxygen surface) were studied.

Fig 2: Compressive load on montmorillonite with one water layer

Fig 3: Compressive load on montmorillonite with three water layers

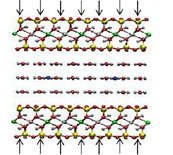

Fig 4: Water molecules after loads applied.

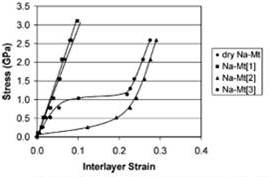

Fig 5: Interlayer stress-strain plot for with dry, 1, 2 and 3 water layers

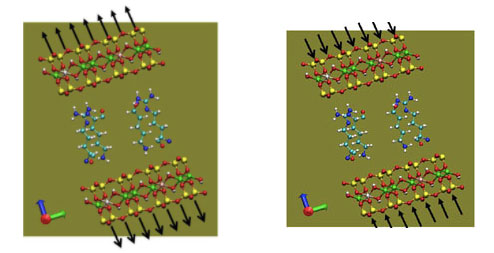

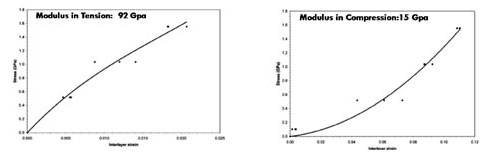

The sodium ions in montmorillonite were replaced by positively charged amino acids and then the load deformation characteristics of the interlayer were studied under tensile and compressive stress path. Attempts were also made to understand the interactions of the amino acid molecules with the clay.

Fig 6: Montmorillonite with positively charged amino acids under tension and compression

Fig 7: Stress-Strain plot under tension and compression

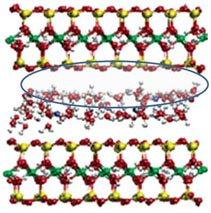

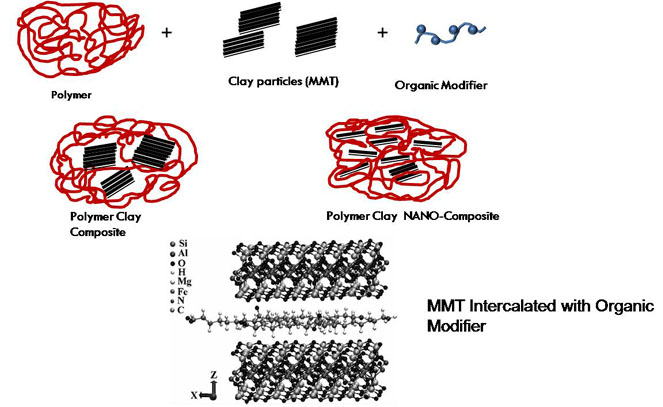

Montmorillonite clay is extremely detrimental to civil engineers because of its expansive nature. However, it is the same expansive nature or the ability to undergo expansion or exfoliation that makes montmorillonite attractive to the material scientists for the synthesis of polymer clay nanocomposites (PCN). In In PCN. polymers (such as nylon 6) are reinforced with clay particles which has one of its dimension in the nanometer range and thus the name nanocomposite. Clay is usually hydrophophilic in nature. It is modified with some organic modifier to turn in hydrophobic before it is actually mixed with the polymer matrix.

The major objectives of this research were to find the interaction between different components of PCN and also to understand if the organic modifiers contribute to the mechanical properties of PCN. Both experimental and modeling techniques were applied.