Research Details

Title : Vibration Based Fault Diagnosis and Life Estimation of a Rotor System

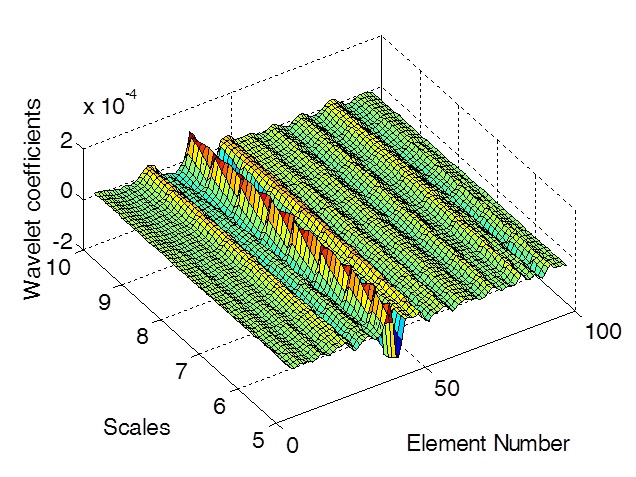

In high speed rotating machinery, components like shafts are subjected to continuous operation which generates rapidly fluctuating bending stresses can induce fatigue damages. Fatigue damages are severe threat to integrity of the vibrating structure.Hence, the diagnosis of fatigue crack location identification, quantification and fatigue crack initiation life in uninterrupted rotating systems is still an active and challenging research problem in equipment predictive maintenance. Many detection techniques have been proposed based on different available measured or simulated data. For instance, the use of operating deflection shape (ODS) data to detect fatigue damage is a promising and realistic approach that is being increasingly investigated. The ODS, which represents the deflection of a vibrating structure at a particular frequency to a specific structural loading, has been gaining importance for crack detection in recent years. Obtained ODS data of a cracked is processed, using different advance signal processing techniques to detect, localize and quantify the fault severity. The performance of various techniques in detecting fault (using obtained simulation data) has to be tested by including different levels of noise.

Fatigue life analysis of rotating components requires real-time vibration data, mostly in the form of stress or strain time history.. As the response time history measured from typical rotating machinery is mostly random in nature, in this case different approaches like time and frequency domain analysis can be employed in evaluating fatigue crack initiation life. The most important objective in the development of modern design approach is the accurate assessment of the fatigue life of critically stressed rotating components.

Figure 1: Damage detected with displacement ods for 10db noise.

Figure 2:Double damage detected with displacement ods for 10db noise.

Figure 3: Single damage detected with strain energy ods for 10db noise.

Figure 4: Double damage detected with strain energy ods for 10db noise.