Research Areas:

Solid Oxide Fuel Cells

Energy Materials

Batteries, Zn-air and Zn-ion Battery

Friction Stir Welding and Processing

Al and Ti based Metal Matrix Composites

EBSD and TEM

Solid Oxide Fuel Cells (SOFC)

Solid oxide fuel cell is a device that converts chemical energy to electrical energy. This is one of the most promising green technologies of energy generation. Three major components of an SOFC are electrolyte, anode and cathode. Stabilized zirconia and doped ceria are commonly used electrolyte materials and other materials like LaGaO

3, brownmillerite structures have been also explored as electrolyte. A cermet of Ni and yttria stabilized ziconia (YSZ), Ni-YSZ, is the most commonly used anode material having the required properties of an anode. LaMnO

3 doped with Sr (LSM) is the commonly used cathode.

Our group is primarily working on the development of electrolyte materials for SOFCs. Systems like Scandia stabilized zirconia (SSZ) co-doped with rare earths, multiple doped ceria and and BaCeO

3 and BaZrO

3 based proton conductors have been investigated. We are also working towards understanding the degradation mechanism of SOFCs by single cell testing that will possibly be scaled up to stack level in future.

Electrochemical Impedance Spectroscope (EIS)

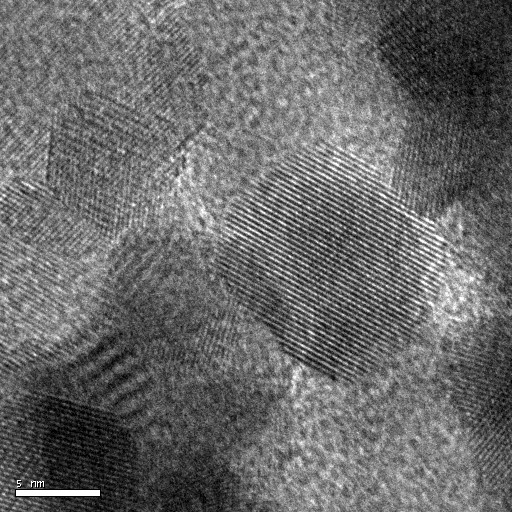

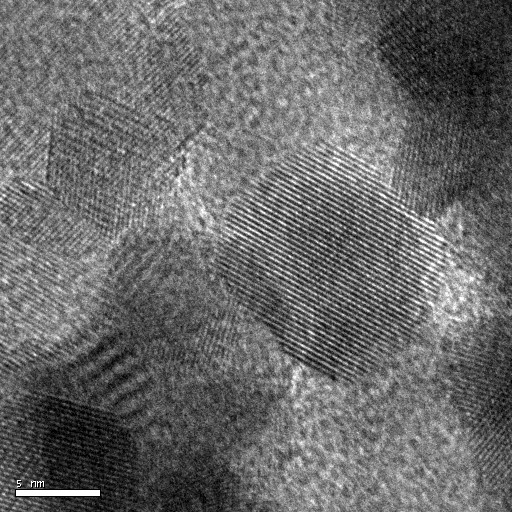

HR-TEM of GDC-BaCeO

3 nano composite

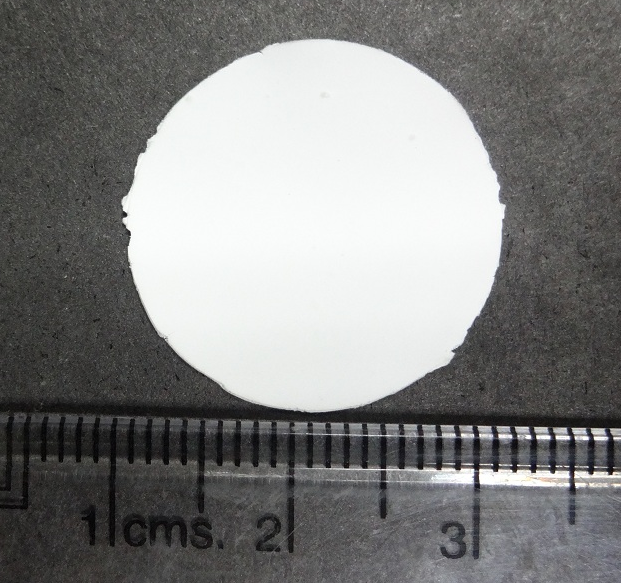

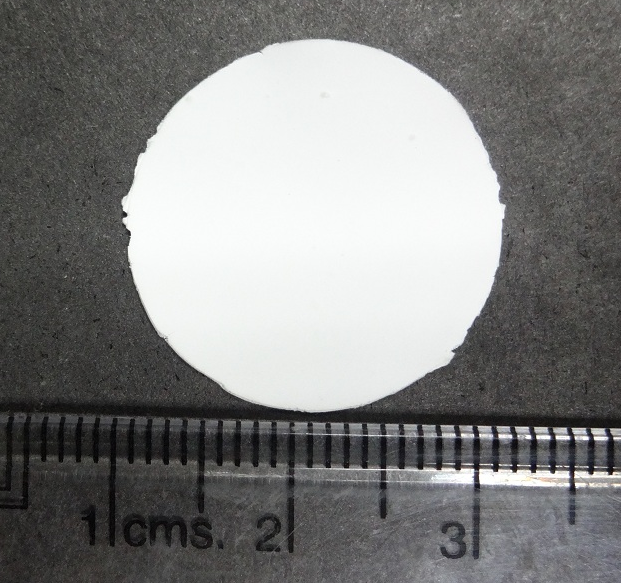

YSZ sintered tape

Ni-YSZ anode

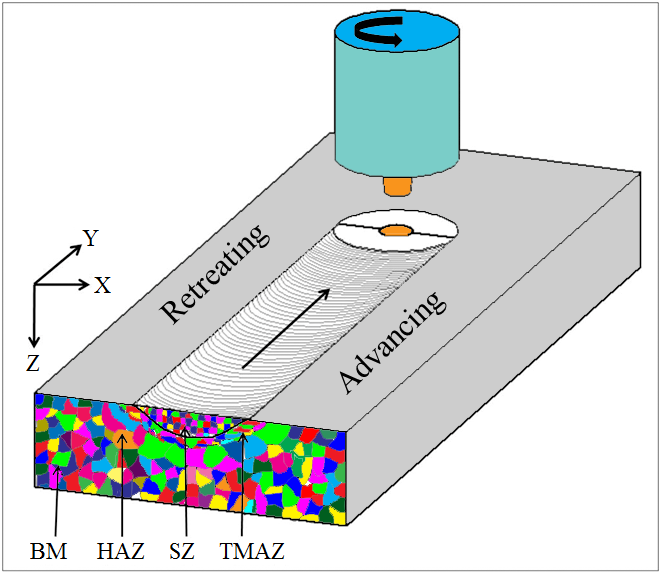

Friction Stir Welding and Processing (FSW & FSP)

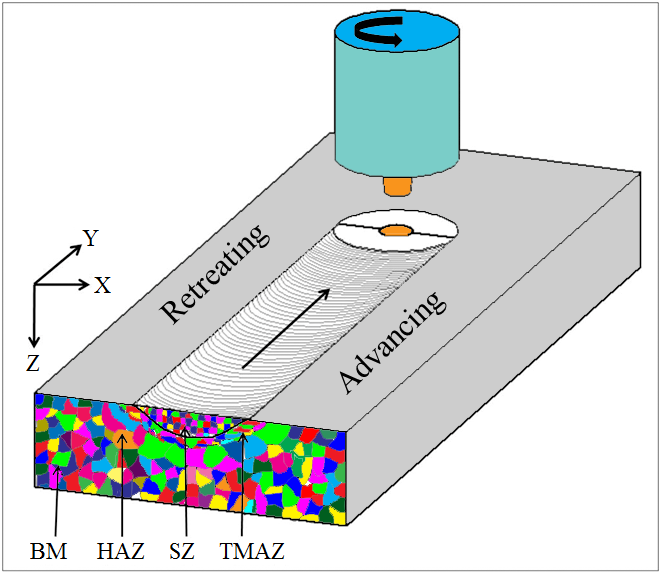

Friction Stir Welding (FSW) is an ideal joining technique to weld materials like Aluminium alloys which are difficult to join by fusion welding methods. FSW has found applications in automotive, aerospace and several other manufacturing industries. FSW uses a non consumable cylindrical tool containing a shoulder and a pin that rotates at a desired rpm and is traversed into the workpiece at a desired speed along a certain length to join it. Friction stir processing (FSP), which is based on the principle of FSW, has been emerging as a versatile tool for microstructure modification and grain refinement. We primarily study the microstructure-property correlation in these processes and as such are involved in detailed investigations to understand the microstructure evolution during the process. We have developed FSW process parameters window for new generation aluminium alloys for light-weight automotive parts. We have also investigated the precipitation behaviour and the effect of FSW/FSP on the same.

Schematic of FSW/FSP

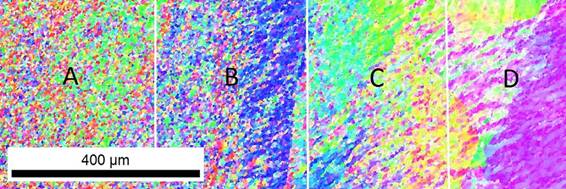

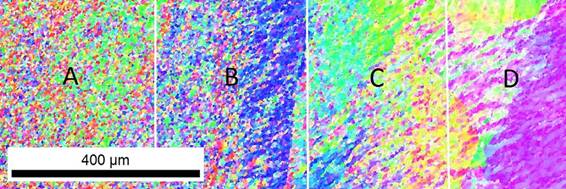

EBSD image of FSPed Al. A. Stir zone(SZ) B. TMAZ C. HAZ D. Base metal (BM)